APPLICATION:

EVA, PE, RUBBER, SBR, NBR, CR, EPDM,etc.Splitting.

Function:

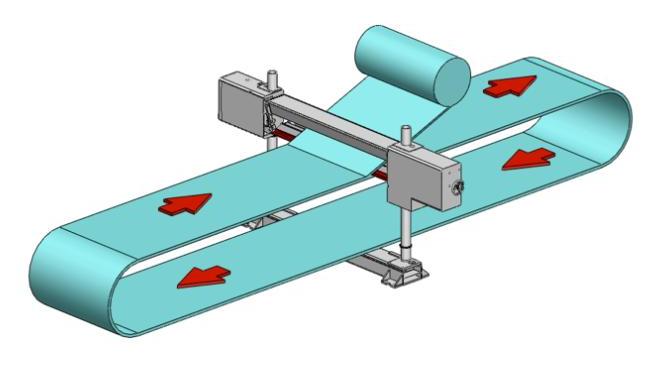

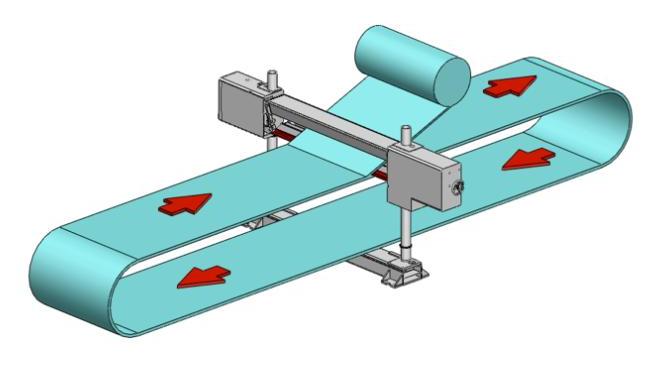

* Loop splitting operation

Operation Mode:

Characteristics:

* With welding device can join EVA or PE into a roll for loop splitting.

Splitting and collecting in one. Not like traditional production lines that need several small machines to work together.

*Automatically adjusting of thickness every splitting is controlled by PLC. Only leave 3 mm on the table. Save more labor than traditional Loop splitting. (transfer and collect roller time)

*Block is automatically balanced and re-located by PLC, don't need people to fixate the material while the block is lost balance.

*Only need one person for operation, save labor. (Traditional production lines need 3~4 people)

FEATURES:

* Friendly PLC inter-face, computer touch screen. Easy to operate.

* Thickness controlled and re-located by PLC.

* The position of blade controlled and re-located by PLC.

* Raw material sheet is aligned and re-located by PLC.

* Multiple functions:

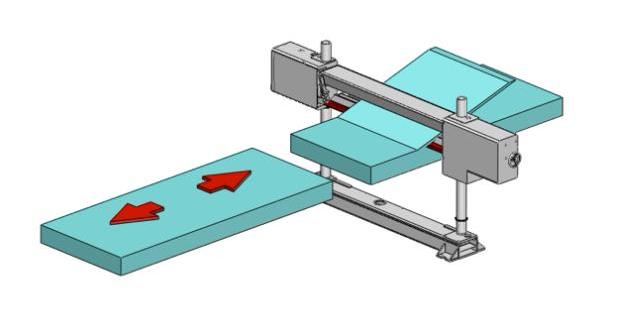

1. Single Sheet Splitting.

2. Loop Splitting.

* Automatic sliced piece counting function.

* Automatic sliced length counting function.

* Dusty collector for blade sharpener.

- Specifications

- Description

- Video

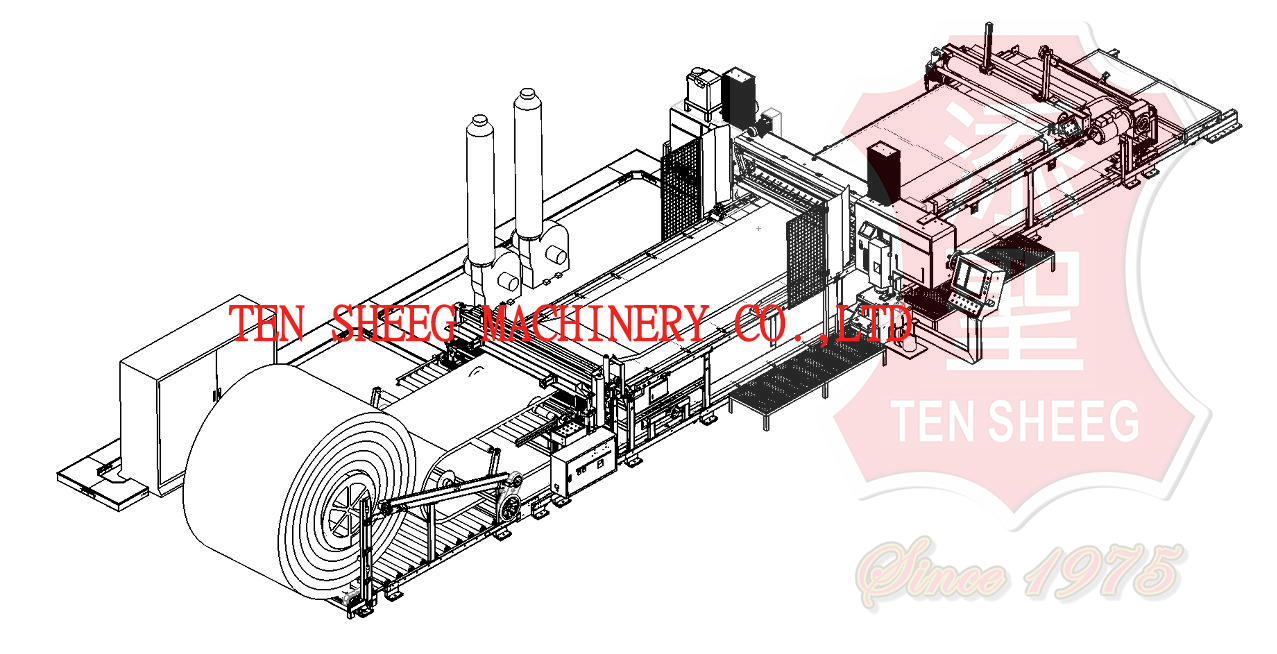

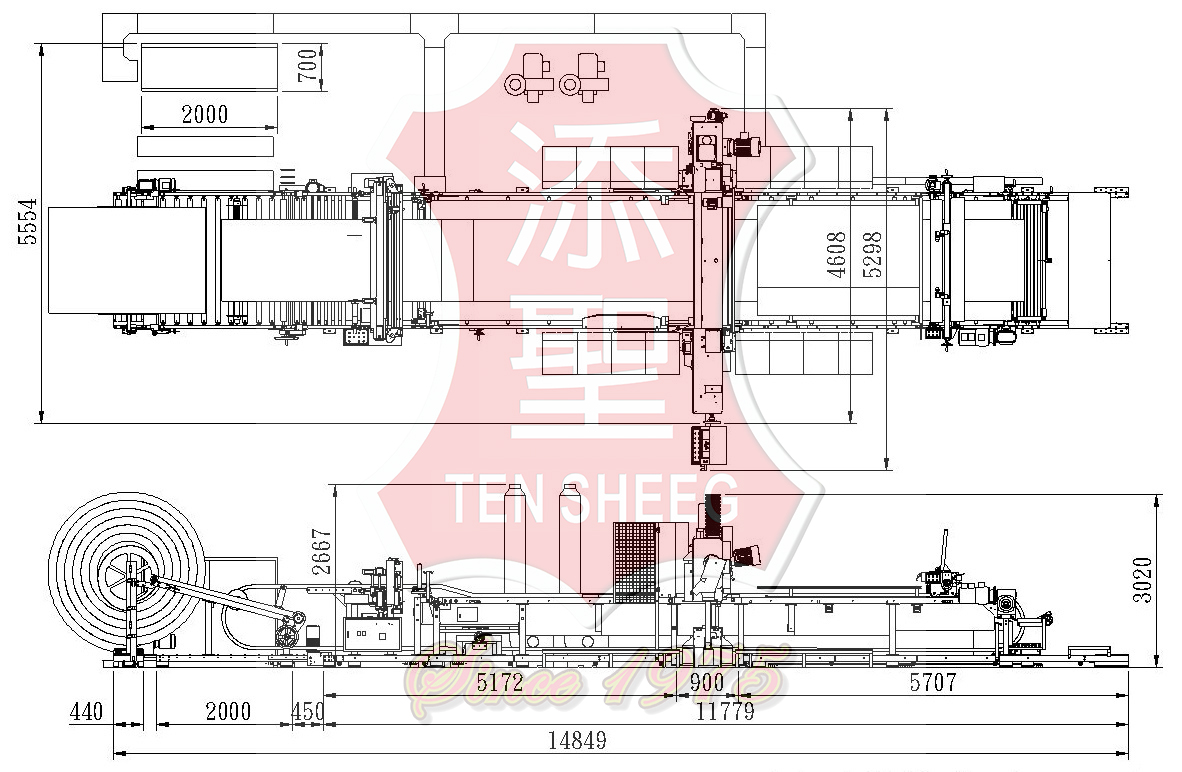

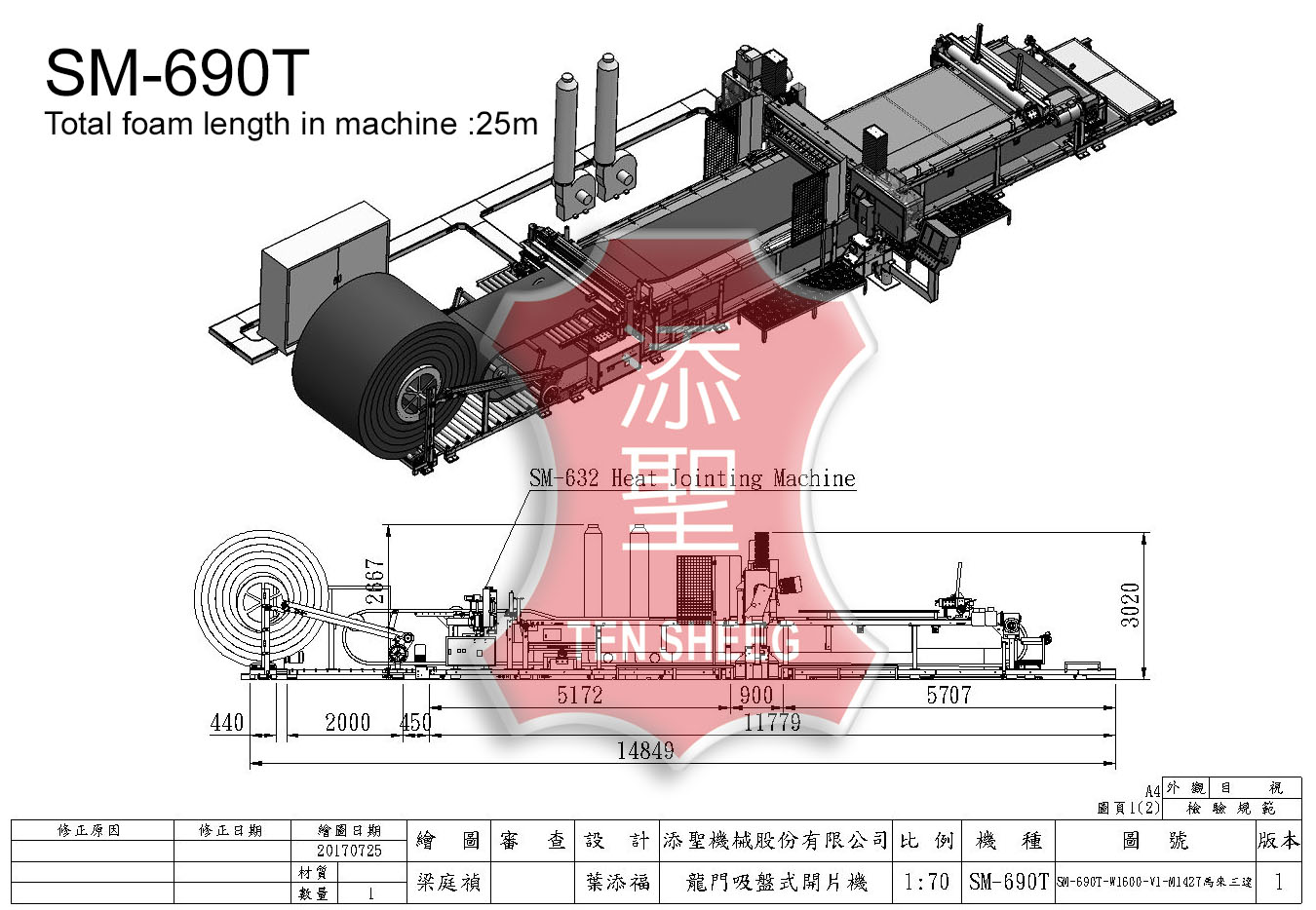

- Layout

- Consumables

| Foam Transfer Method | By Vacuum conveyor | |

| Max. Block Height | 120 | mm |

| Total Power | 36 | HP |

| Total Vacuum Power | 7.5 X 2 | HP |

| Vacuum Power | 420 | mmAq (mmWs) |

| Upper conveyor Power | 5 | HP |

| Lower conveyor Power | 1 | HP |

| Winding Roller Power | 1 | HP |

| Jointing Machine Included | YES | SM-632 |

| Triming Method | Heating knife trimming | |

| Jointing Method | Heating Knife Jointing | |

| Heating Knife Driving Motor | 0.5 | HP |

| Push Jointing motor | 0.25 | HP |

| Splitting Foam | EVA / PE / TPE…etc. | |

| Driving Inverter | TECO Yasukawa |

|

| Driving Motors | TECO Fukuta |

|

| Cutting Structure Foam | Casting Steel | |

| Foam FWD Speed | Up to 50 | m/min |

| Foam BWD Speed | Up to 70 | m/min |

| Final Layer | 3 | mm +-0.5mm |

| Splitting Hardness | 3~60 | degree (Shore C) |

| Min. Splitting Layer | 0.2 | mm |

| Splitting Tolerance | +/-0.05 or 1% | mm |

| Knife Beam | 12 | degree |

| Knife speed | 5.5 | m/sec @ 50Hz |

| Knife driving motor | 7.5HP 4P | |

| Knife driven wheel | Cast Iron | Ductile iron |

| Knife wheel diameter | 600 | mm |

| Thickness Setting Accurance | 0.01 | mm |

| Counting Function | YES | |

| Grinding Dust Exhausting Device | YES | |

| Grinding dust vacuum motor | 1.5HP 2P | |

| Knife sharpening motor | 1HP 4P x 2pcs | |

| Thickness Auto Adjusting | YES | PLC Controlled |

| Cutting head Up/Down | 2HP | Fukuta |

| Head Up/Down reducer | TDVM2 | Sumitomo |

| Knife Edge Position | YES | PLC Controlled |

| Knife position motor | 1/8 HP | Li-Ming |

| Press Roller | YES | |

| Press Roller Height Pos | YES | |

| Foam Pass above Knife | 50 | mm |

| Feeding roller motor | 1 HP | Fukuta |

| Feeding roller motor reducer | TVM | Transycko |

| Recipe Management | Yes |

- This model of automatic splitting machine has a welding device which can bond the first and last piece of EVA or PE into a loop for loops splitting.

- Splitting and collecting in one. Not like traditional production lines that need several small machines to work together.

- Automatically adjust of thickness while every loop completed is controlled by PLC. Only leaves 3mm on the table. Will save more labor than traditional loop splitting machine(feeding and changing roller's time).

- Material Working Concept:

| Part No. | Name | Picture |

| 689E10 | Blade Table Pusher Set(For 1.6M) |  |

|

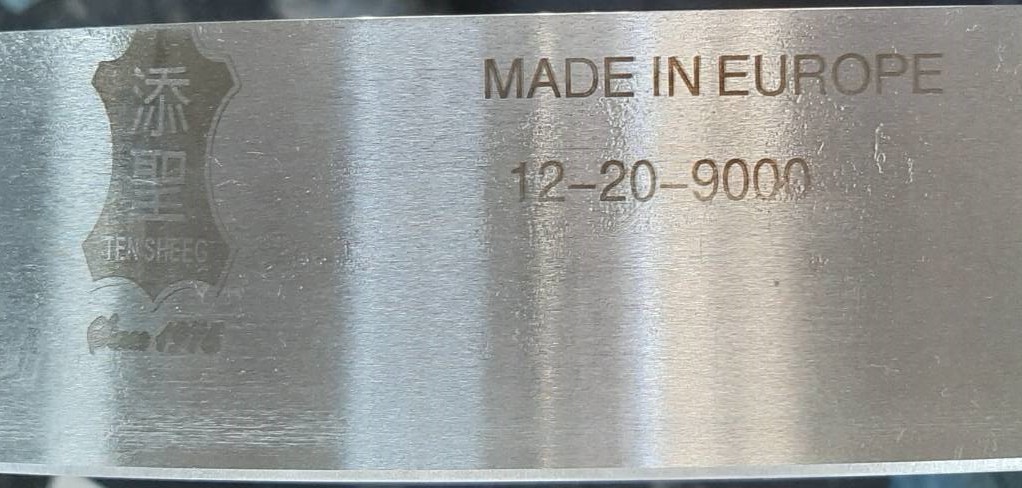

689E100 |

Band-knife |  |

|

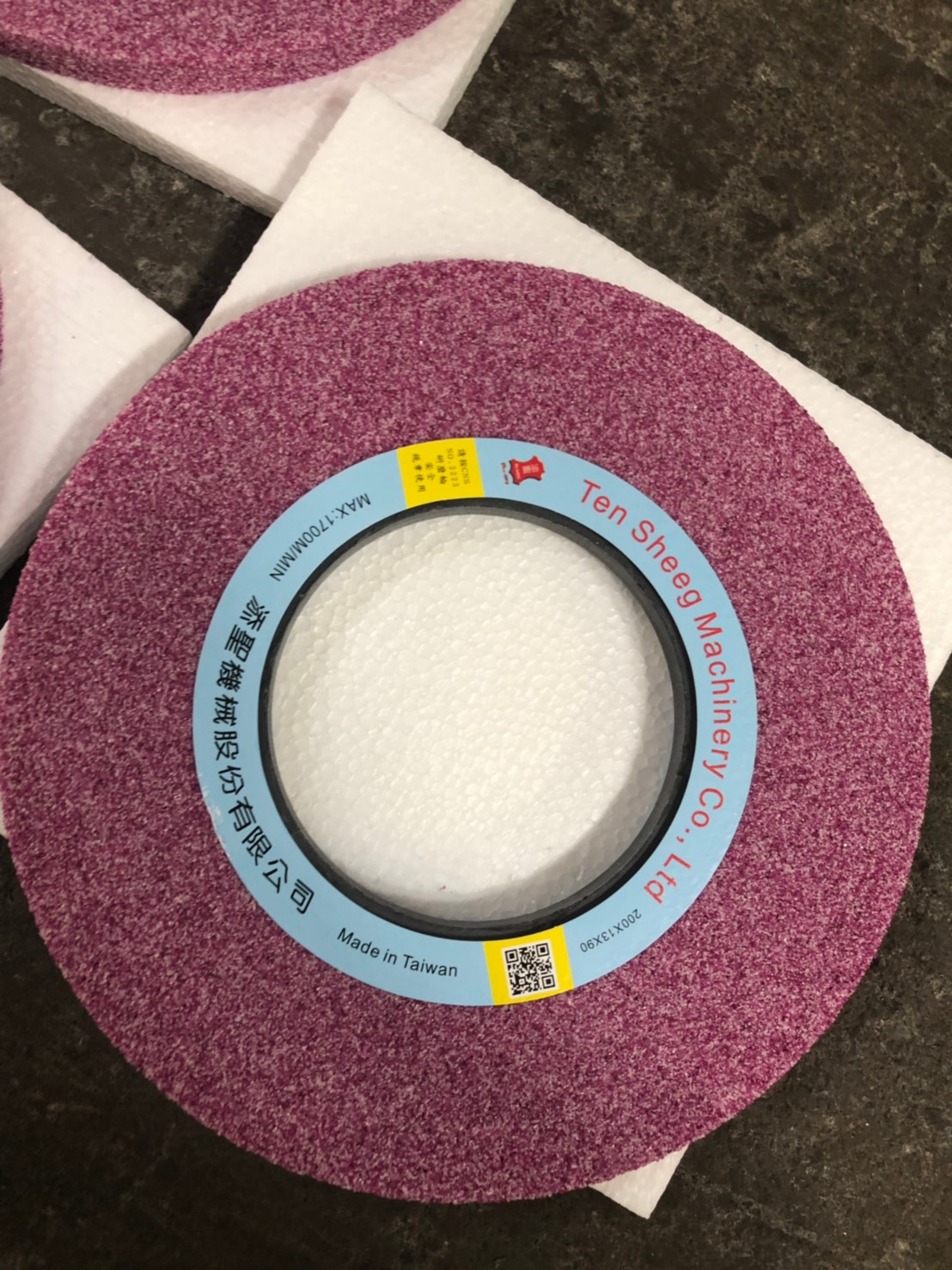

689F416 |

GRINDSTONE |  |

| 689F110 | Diamond dresser Set For Grinding Wheel |  |

| 689E30 | Blade locator Pusher(Set) |  |

| Part No. | Description | Spare for one year | Unit |

| 688J308 | Sendor Knife edge | 1 | PCS |

| 689F402 | Blade lcated seat | 1 | PCS |

| EL0105 | Sensor for knife limination position | 2 | SET |

| 689F416 669D406 |

Knife Grinding Stone | 4 | PCS |

| 689F110-1 | Diamond dresser head (Grinding stone cleaner) |

4 | PCS |

| 689F110 669D501 |

Diamond dresser set (Grinding Stone Cleaner whole set) |

2 | SET |

| 689E104 | Band-knife locator backsplash 1.6m | 1 | PCS |

| 689e100 | Knife 1mm X 60mmX 9000mm | 10 | PCS |

| 689E102 | Bottom band-knife fixed plate 1.6m | 1 | PCS |

| 689E103 | Upper band-knife fixed plate 1.6m | 1 | PCS |

| 689E10 | Band-knife position screw set (Knife holder section) |

6 | SET |

| 689E30 | Band-knife position screw set (Wheel holder section) |

1 | SET |

| 689F40 | Band-knife position screw set (Grinding stone section) |

1 | SET |

| 689A304 | Encoder HTR-6C-1000-2-x180 Main Cutting head height |

1 | PCS |

| 689G514 | EHW-200 encoder Feeding roller height |

1 | PCS |

| 689C408 | Knife Cleaning Blanket | 2 | PCS |

| 689F403 | Knife sharpening fixed plate | 1 | PCS |