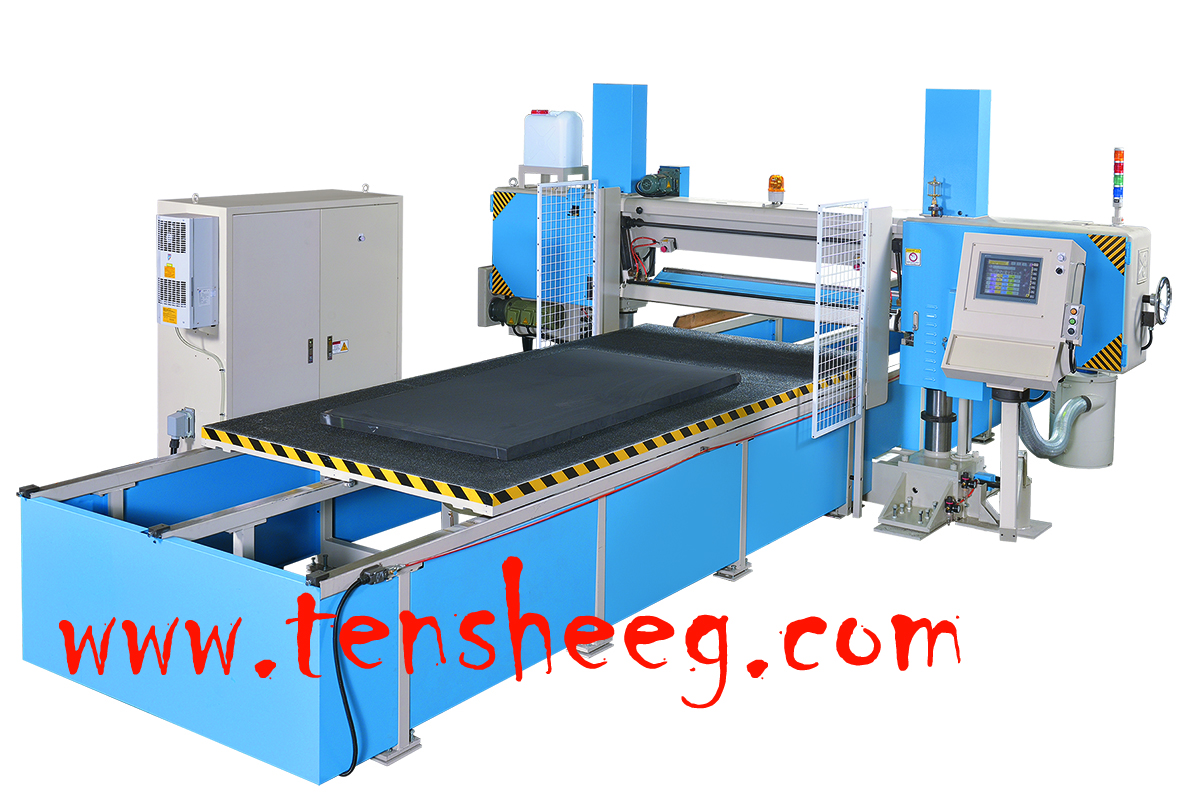

APPLICATION:

EVA,PE,RUBBER,SBR,NBR,CR,EPDM,etc... foam Splitting.

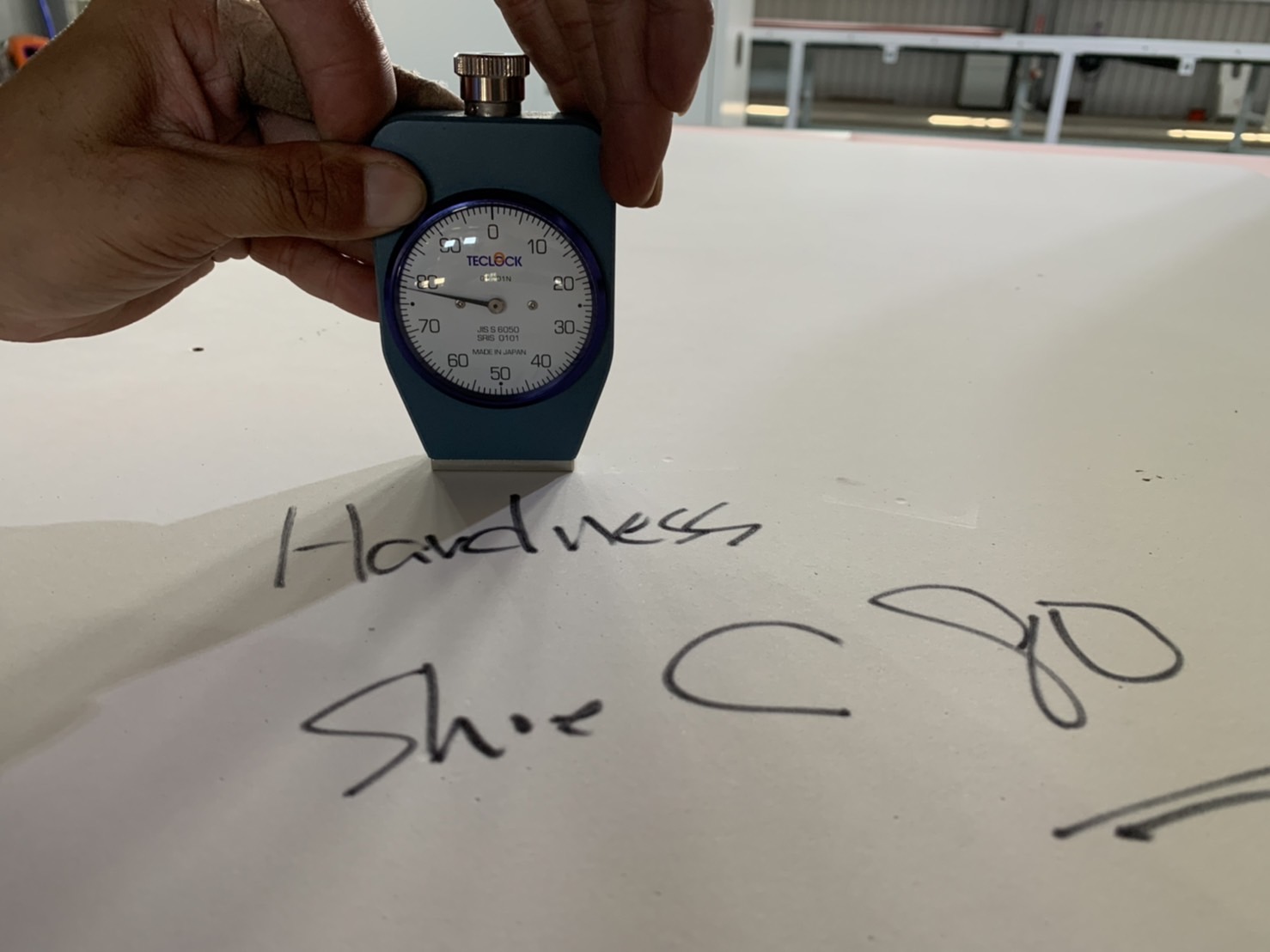

Hardness to Split:

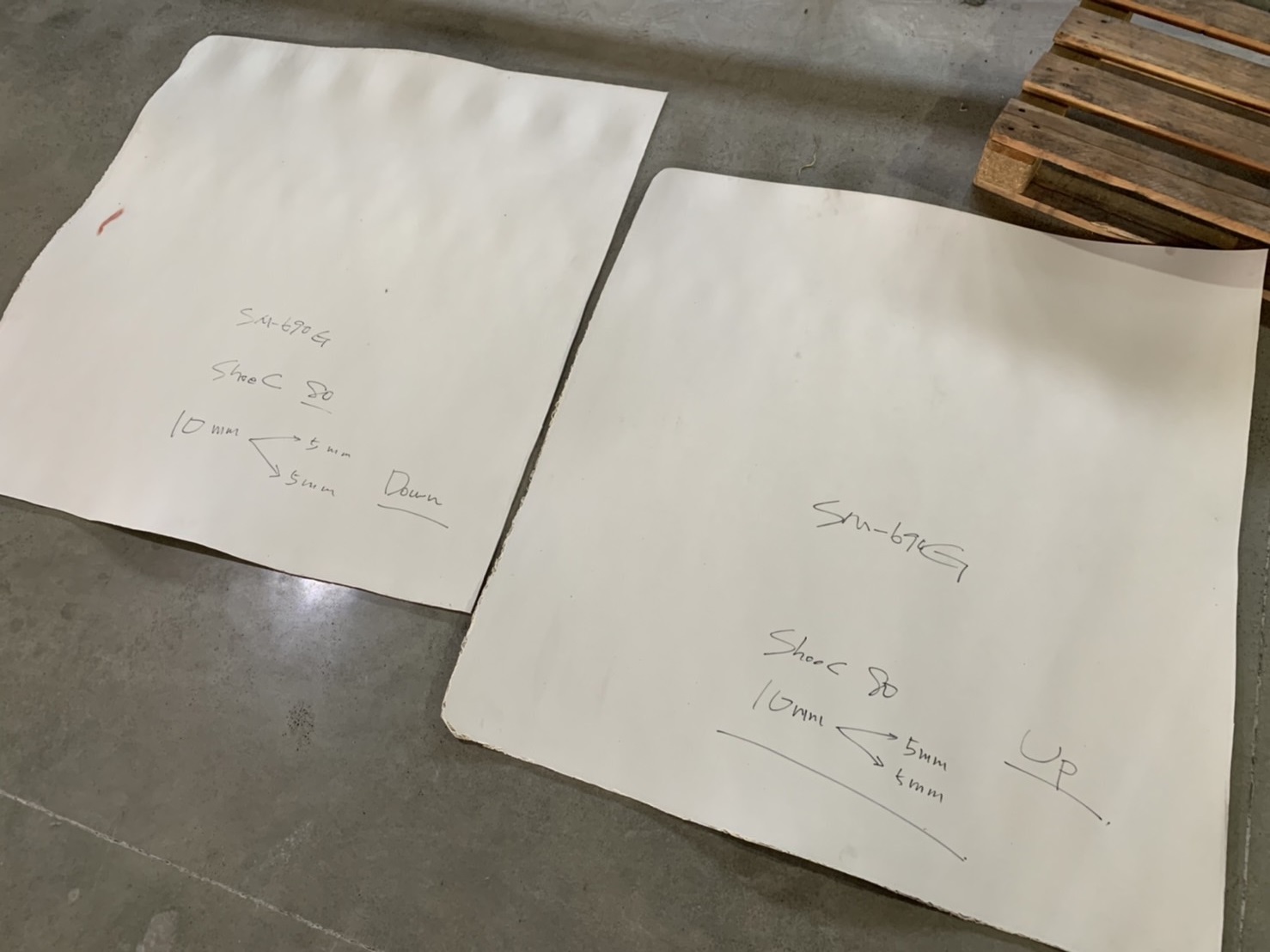

SM-690C Hardness to split up to 70 Shore C. Thickness 3mm

SM-690G Hardness to split up to 80 Shore C. Thickness 5mm

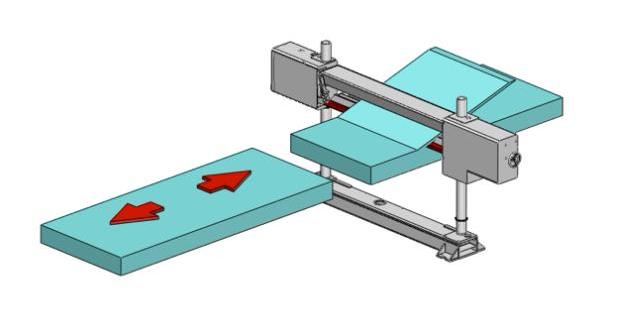

Operation Mode:

Characteristics:

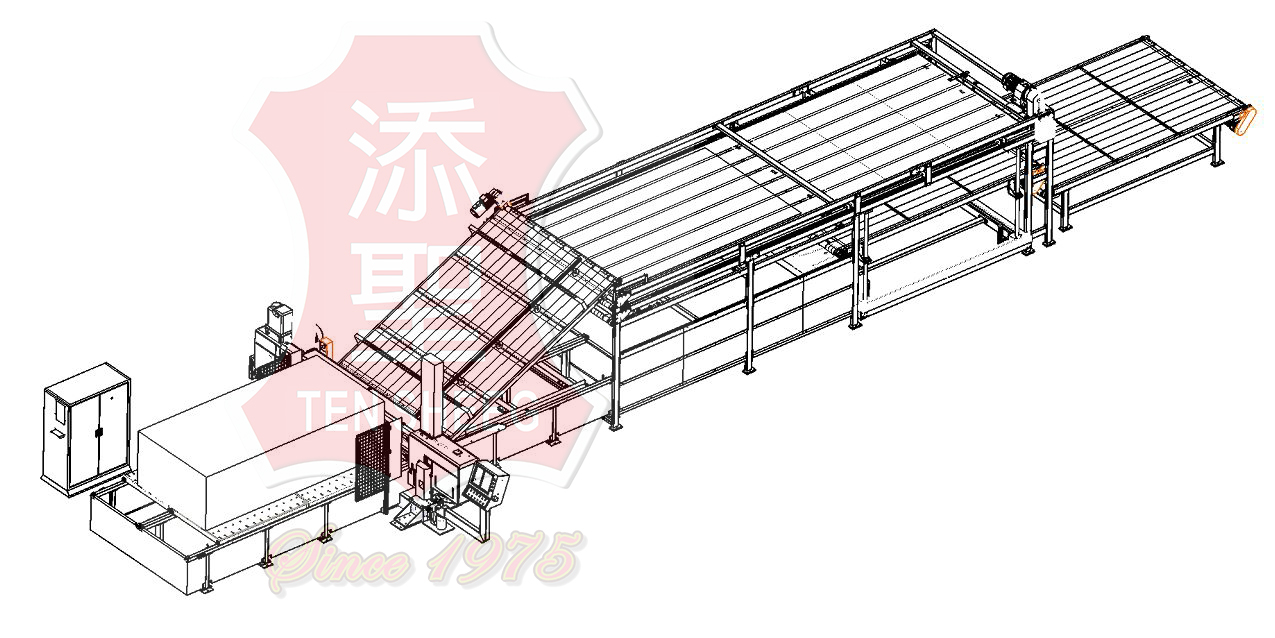

*Automatic reciprocating and forward splitting Saves transfer time of raw material. Increases productivity.

*Automatically thickness adjusting PLC controls every splitting. Only leave 3mm on the table save labor than traditional loop splitting (transfer time).

*Only need one person for operation (collecting finished products). Save labor (a traditional type of needs one person to feed raw material block and two people to collect products).

FEATURES:

* Friendly PLC inter-face, computer touch screes.Easy to operate.

* Thickness controlled and re-located by PLC.

* The position of blade controlled and re-located by PLC.

* Automatic Sliced Piece Counting Function.

* Dusty collector for blade sharpener.

* Close tolerance: +/- 0.1mm (When starting with level material)

- Specifications

- Description

- Video

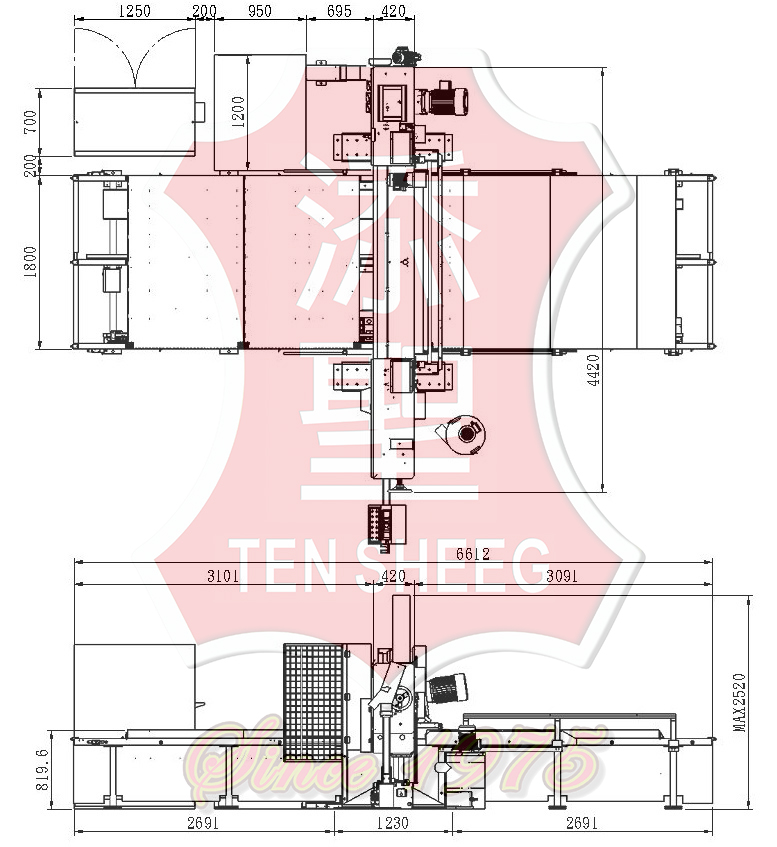

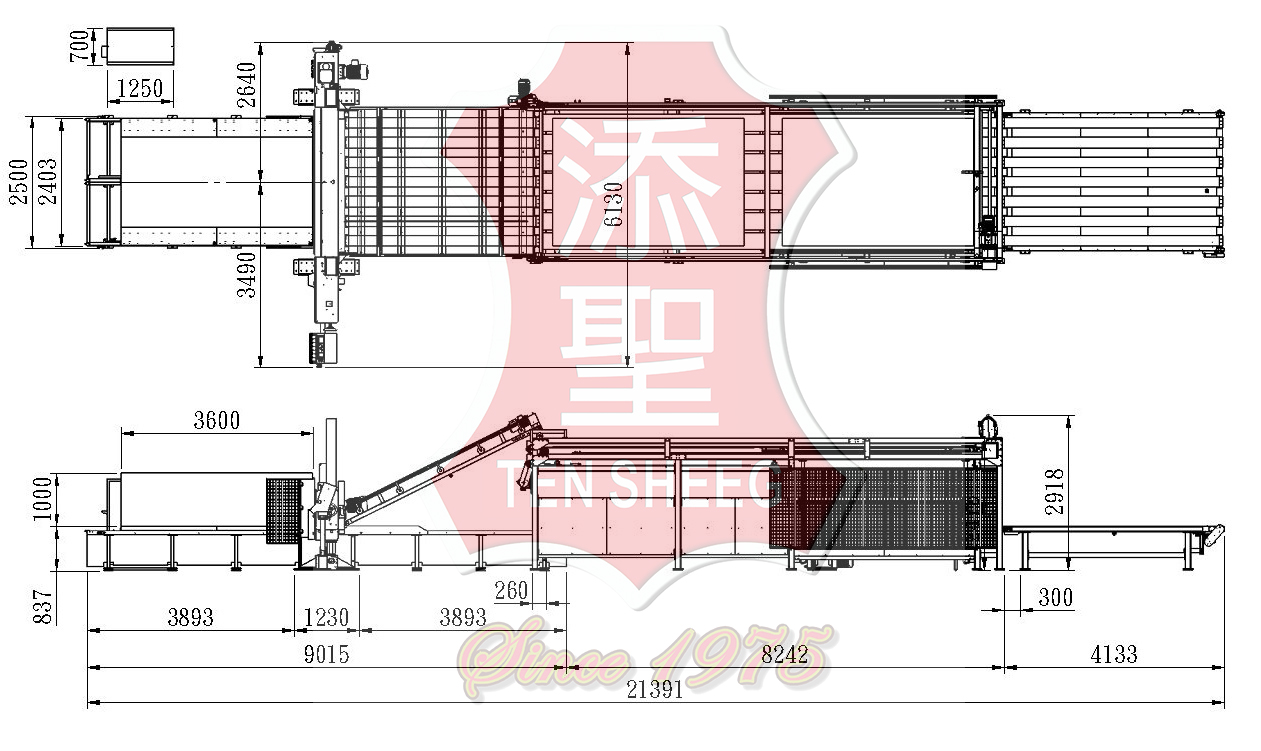

- Layout

- Consumables

| Foam Transfer Method | By Vacuum Table | |

| Max. Block Height | 200 / 1000 | mm |

| Vacuum Table Length | 2400 / 3600 | mm |

| Total Power | 26 / 29 | HP |

| Total Vacuum Power | 3x2 / 3x3 | HP |

| Vacuum Power | 280 | mmAq (mmWs) |

| Machine Length | 6600 / 9000 | mm |

| Max. Block Width | 1300 / 1600 | mm |

| Knife width | 60 | mm |

| Knife Thickness | 1 | mm |

| Knife Length | 8380 / 9000 | mm |

| PLC | Mitsubishi | FX-3U |

| Touch Panel | ProFace | GP-4502W |

| Driving Inverter | TECO Yasukawa |

|

| Driving Motors | TECO Fukuta |

|

| Cutting Structure Foam | Casting Steel | |

| Foam FWD Speed | Up to 50 | m/min |

| Foam BWD Speed | Up to 70 | m/min |

| Final Layer | 3 | mm +-0.5mm |

| Splitting Hardness | 3~60 | degree (Shore C) |

| Min. Splitting Layer | 0.2 | mm |

| Splitting Tolerance | +/-0.05 or 1% | mm |

| Knife Beam | 12 | degree |

| Knife speed | 5.5 | m/sec @ 50Hz |

| Knife driving motor | 7.5HP 4P | |

| Knife driven wheel | Cast Iron | Ductile iron |

| Knife wheel diameter | 600 | mm |

| Thickness Setting Accurance | 0.01 | mm |

| Counting Function | YES | |

| Grinding Dust Exhausting Device | YES | |

| Grinding dust vacuum motor | 1.5HP 2P | |

| Knife sharpening motor | 1HP 4P x 2pcs | |

| Thickness Auto Adjusting | YES | PLC Controlled |

| Cutting head Up/Down | 2HP | Fukuta |

| Head Up/Down reducer | TDVM2 | Sumitomo |

| Knife Edge Position | YES | PLC Controlled |

| Knife position motor | 1/8 HP | Li-Ming |

| Press Roller | YES | |

| Press Roller Height Pos | YES | |

| Foam Pass above Knife | 50 | mm |

| Feeding roller motor | 1 HP | Fukuta |

| Feeding roller motor reducer | TVM | Transycko |

| Recipe Management | Yes |

|

Splitting 70 Shore C Material 16 Second / PC |

SM-682 AMS(Automatic Material Stocking)

|

|

Split EPDM 1 mm at speed 8M/min (One sheet 25 seconds) |

Split EVA 2 mm at speed 30M/min (One sheet 17 seconds) |

|

|

| Part No. | Name | Picture |

| 689E10 | Blade Table Pusher Set(For 1.6M) |  |

|

689E100 |

Band-knife |  |

|

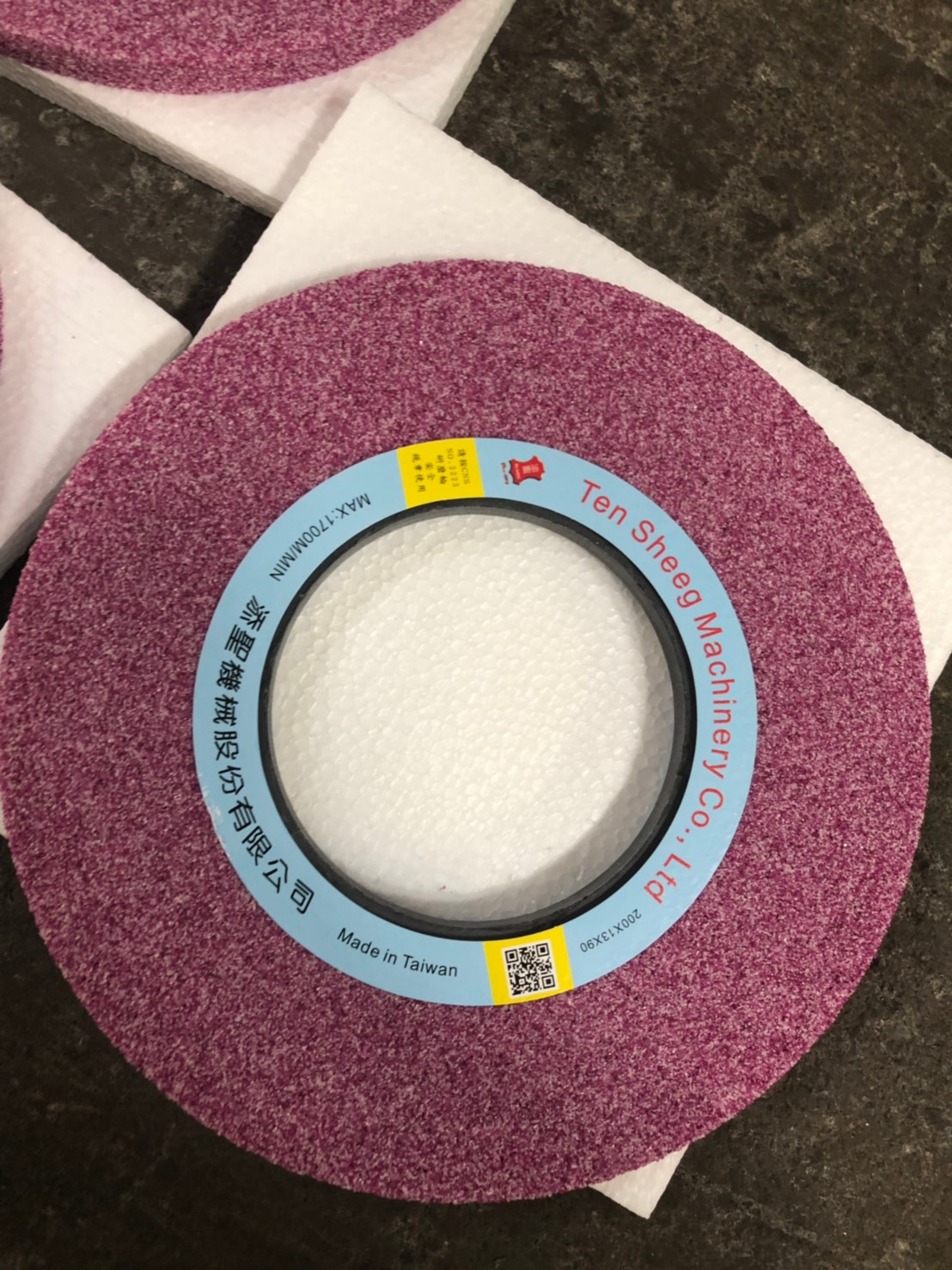

689F416 |

GRINDSTONE |  |

| 689F110 | Diamond dresser Set For Grinding Wheel |  |

| 689E30 | Blade locator Pusher(Set) |  |

| Part No. | Description | Spare for one year | Unit |

| 688J308 | Sendor Knife edge | 1 | PCS |

| 689F402 | Blade lcated seat | 1 | PCS |

| EL0105 | Sensor for knife limination position | 2 | SET |

| 689F416 669D406 |

Knife Grinding Stone | 4 | PCS |

| 689F110-1 | Diamond dresser head (Grinding stone cleaner) |

4 | PCS |

| 689F110 669D501 |

Diamond dresser set (Grinding Stone Cleaner whole set) |

2 | SET |

| 689E104 | Band-knife locator backsplash 1.6m | 1 | PCS |

| 689e100 | Knife 1mm X 60mmX 9000mm | 10 | PCS |

| 689E102 | Bottom band-knife fixed plate 1.6m | 1 | PCS |

| 689E103 | Upper band-knife fixed plate 1.6m | 1 | PCS |

| 689E10 | Band-knife position screw set (Knife holder section) |

6 | SET |

| 689E30 | Band-knife position screw set (Wheel holder section) |

1 | SET |

| 689F40 | Band-knife position screw set (Grinding stone section) |

1 | SET |

| 689A304 | Encoder HTR-6C-1000-2-x180 Main Cutting head height |

1 | PCS |

| 689G514 | EHW-200 encoder Feeding roller height |

1 | PCS |

| 689C408 | Knife Cleaning Blanket | 2 | PCS |

| 689F403 | Knife sharpening fixed plate | 1 | PCS |